As a technology-driven mining company, HOT can provide high-quality One-stop Service for coal washing plant and mineral processing plants of gold, copper, lead, zinc, iron, barite and kaolin. The service content includes project consultation, mineral processing experiment, feasibility study, plant design, equipment supply, installation and commissioning, training and guidance, and mineral processing plant operation and management.

HOT also provides automation and intelligent upgrade service for the plant. HOT aims to provide clients with the most cost-effective and reliable project in terms of process flow, equipment selection and engineering quality, and deliver first-class mineral processing plants to customers.

Feasibility Study and Mineral Processing Experiment

The feasibility study is an important preparation for the design of a mine project. Through careful technical and economic analysis, calculation and comparison of project construction conditions, objective and accurate evaluations and conclusions are made to provide final evaluation for investment decisions. HOT can provide clients with high-quality feasibility study services based on a rich project experience and professional expert.

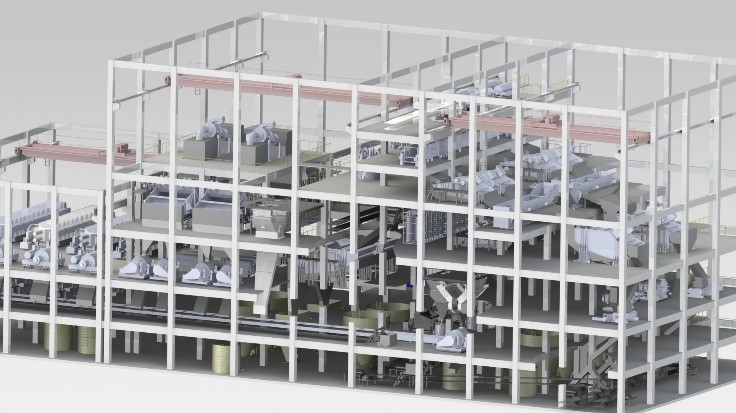

Plant Design

HOT's engineering design teams make the professional and effective mineral processing plant design, based on the results of mineral processing experiment and feasibility studies.

At present, the team have hundreds of professionals in mineral processing, mechanical engineering, electrical, civil engineering, water supply and drainage, etc. All members are rich-experienced in on-site practical, and are familiar with domestic and foreign mining design standards and norms. HOT can provide design services that meet design specifications and are practical and reliable for mineral processing plants of basic metals, rare and precious metals, non-metallic ore and coal preparation plants.

Full-system Equipment Supply

HOT supply full-system equipment through our shareholding companies or cooperative suppliers. All purchased products come from domestic first-line brands. And all the equipment, spare parts and other auxiliary materials have established a dedicated database to strictly test and control equipment in accordance with the quality management system.

Installation & Commissioning

All the installation workers of HOT are professionals with long-term installation experience and corresponding national qualifications. The Quality Supervision of on-site is guaranteed by engineers who has rich on-site installation and production experience, to timely find and eliminate the hidden dangers and defects in the process of design and installation.

Mineral Processing Plant Intelligent Upgrading

After years of mineral processing experience, HOT has trained a professional automation and intelligent technical team, covering engineering, equipment, electrical, automation, telecommunication, data processing, etc for different mineral processing plant to do the customized automatic or intelligent upgrade services.

The automated upgrade service makes it easy for clients to judge and monitor the operating status of plant and equipment. The Adaptive Big Data Intelligence is one of the core technologies of HOT, which has been applied as a pilot project in a domestic mineral processing plant, and the effect is excellent. This upgrade service greatly reduces personnel operations, and the production indicators have been greatly stabilized and significantly improved.