[Technology Breakthrough]

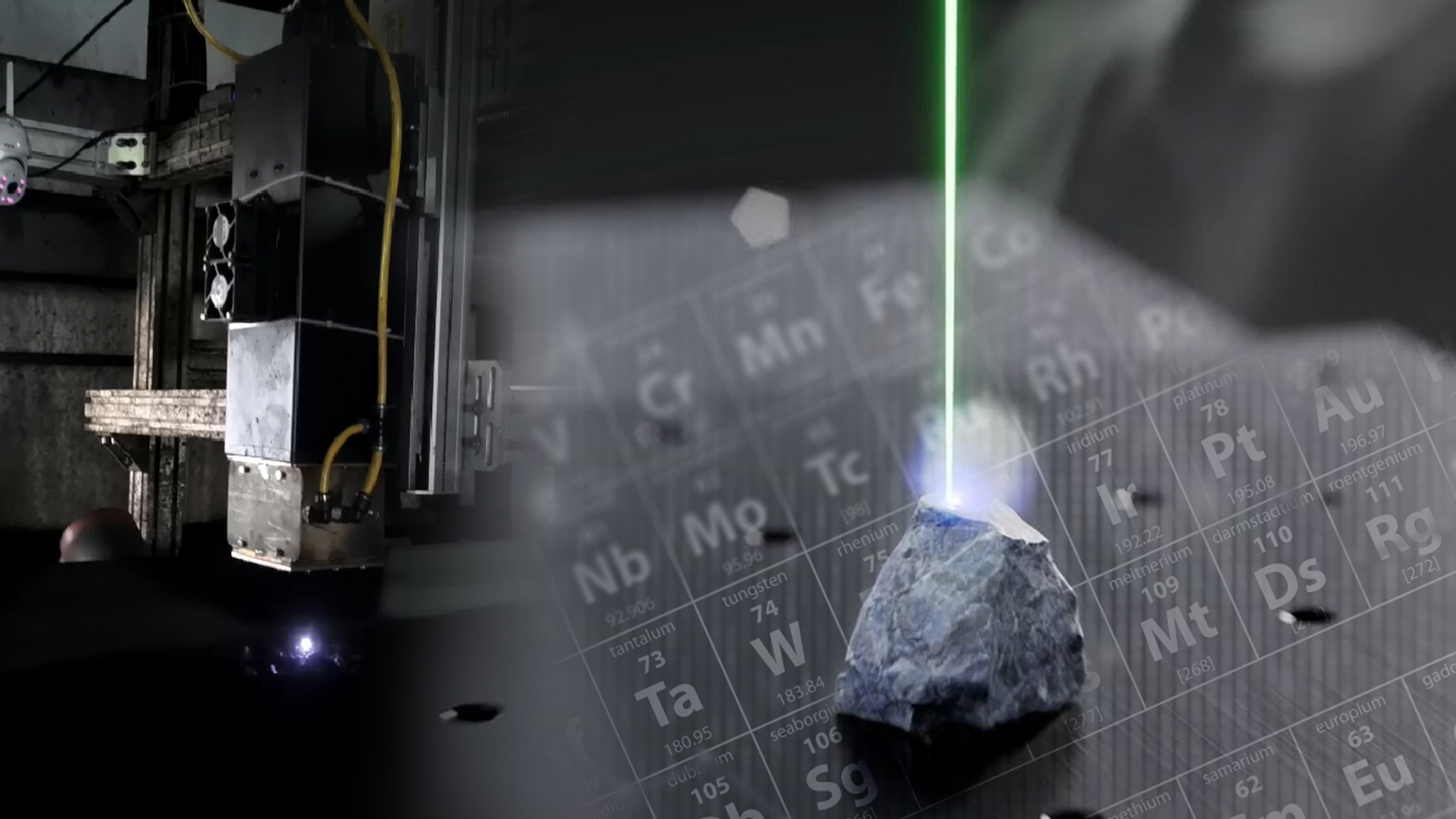

HOT's Dual-Pulse LIBS Brings Lithium into Sharp Focus"Lithium is the white gold of the energy transition—but mining it is like searching for invisible treasure. X-rays miss it, handheld tools are too slow, and labs can't keep up. Here's how HOT's Dual-Pulse LIBS is changing the game:"

The Three Major Blind Spots in Lithium Sorting:

“Like picking diamonds with a blindfold” — Director of Mineral Processing, Lithium Mine

❌ X-rays fail: Lithium atoms are too light to react meaningfully.

❌ Handhelds struggle: No continuous scanning; detection limits remain above 500 ppm.

❌ Lab testing lags: Sampling and analysis take hours—too slow for real-time sorting.

Technical Breakthrough: Three Cores of HOT Industrial Double-Pulse LIBS

Dual-Pulse Laser: 10× Stronger Lithium Signal

1st pulse (532 nm) excites plasma.

2nd pulse re-excites lithium atoms, enhancing weak signals by an order of magnitude.

Smart Spectral Recognition

Targets lithium bands (450–670 nm).

Uses Li/Al or Li/Si ratios to correct interferences dynamically.

Accuracy now reaches 5%, overcoming plasma noise.

Industrial-Grade Hardware, Ready for Production Lines.

Dual-pulse industrial-grade laser system laser system.

Full lithium spectral range (380–800 nm).

<0.2 nm resolution to isolate interfering elements (Ca, Mg).

Field-Proven Performance: Liatam Mine Trials

*Millisecond Response: Real-time scanning synchronized with conveyor belts.

*Smart Sorting: Auto-ejection driven by AI thresholds.

*Dust & Vibration Resistant: Stable even in harsh environments.

The Future Is Now: LIBS as the Core of Smart Mining

What's Next:

Lithium reference databases in development; aiming for <3% quantitative error.

Cloud-based spectral libraries accelerating deposit valuation.

Autonomous mines in pilot testing; expected to cut sorting cost per ton by 40%.

The Profit Equation:

(Real-Time Sorting Efficiency × Concentrate Recovery Rate) ÷ Labor Cost = 300%+ Profit Boost

"What's your biggest challenge in mineral sorting? Let's discuss in the comments—or tag a colleague who needs this tech.