The double toothed roller crusher is a highly efficient and energy-saving crushing equipment, widely used in coal mines, power plants, steel, chemical, cement, limestone, paper-making, and environmental protection industries. It is capable of crushing raw coal, clean coal, limestone, slag, and various non-metallic minerals, ensuring stable feed size for mineral processing, metallurgy, and building materials industries.

The crusher adopts two synchronously meshed toothed rolls:

1. Impact Crushing: Large blocks of material are first fractured by the impact of the crushing teeth;

2. Shearing Crushing: Medium-sized materials are further reduced through shearing and extrusion between the rolls;

3. 3D Size Control: Optional transverse crushing beam achieves three-dimensional size control, ensuring uniform product size with minimal fines.

1. Applicable to materials with compressive strength ≤ 30,000 psi;

2. Supports both primary (coarse) and secondary (fine) crushing;

3. Compact design with low overall height, ideal for space-limited installations;

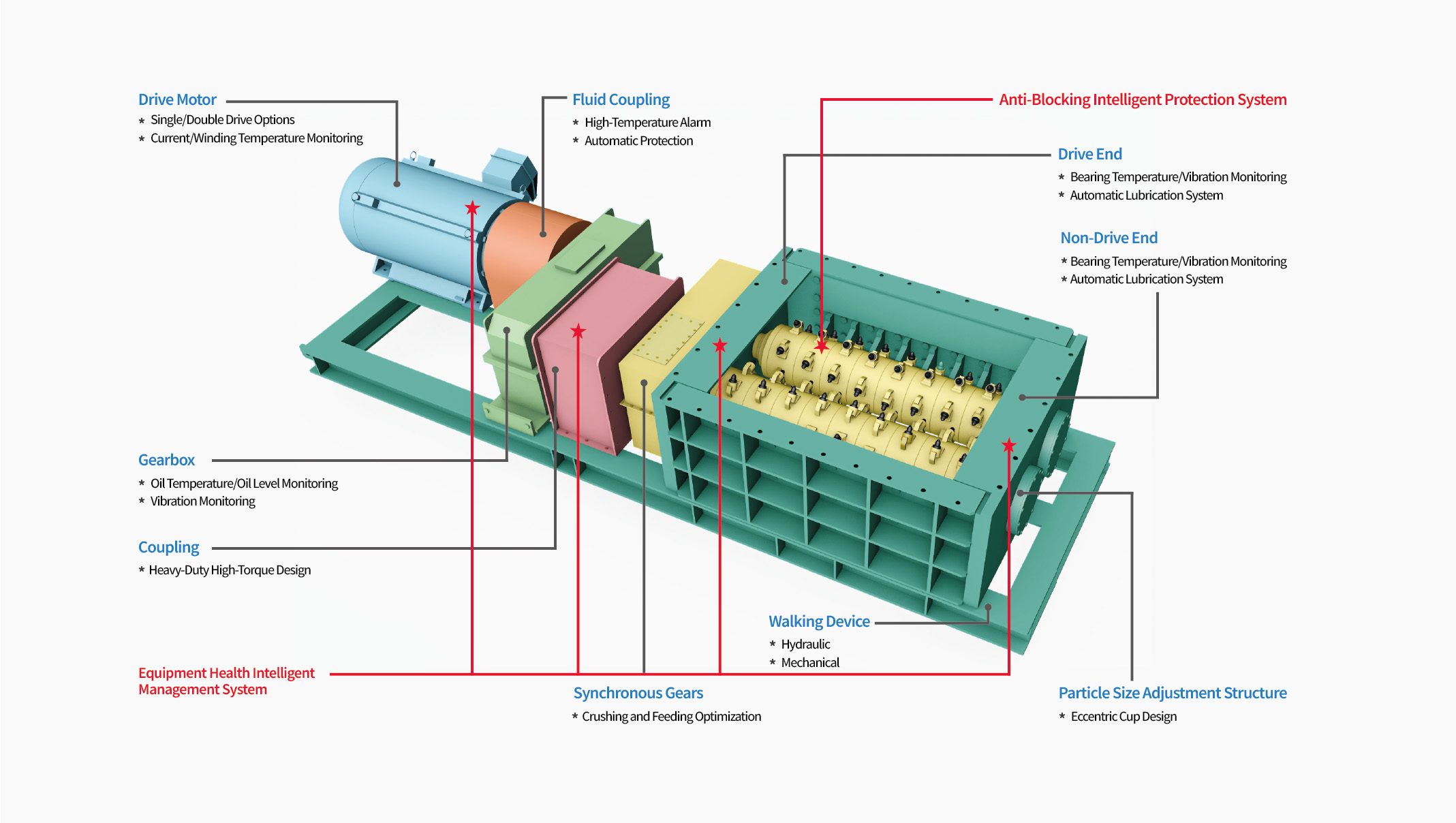

4. Equipped with mechanical or hydraulic travel mechanism for fast machine withdrawal and easy maintenance;

5. Customizable tooth profiles designed for specific material characteristics.

Product Advantages

1. High Efficiency: Crushing teeth engage evenly, delivering higher capacity than conventional crushers;

2. Energy-Saving & Eco-Friendly: Optimized tooth design reduces fines and energy consumption;

3. Flexible Installation: Small footprint and low height make it suitable for complex site conditions;

4. Easy Maintenance: Modular structure allows quick inspection and replacement of wear parts;

5. Wide Adaptability: Performs reliably on coal, limestone, chemical raw materials, building aggregates, and more.

1. Beyond standard models, additional services include:

2. Spare Parts Supply: Various rolls, beams, and other wear components;

3. Technology Upgrades: Performance improvement and equipment optimization;

4. Compatibility Support: Spare parts and maintenance services for mainstream brands such as MMD and ABON.