Ⅰ Current Status and Data of Dense Medium Consumption in Chinese Coal Preparation Plants

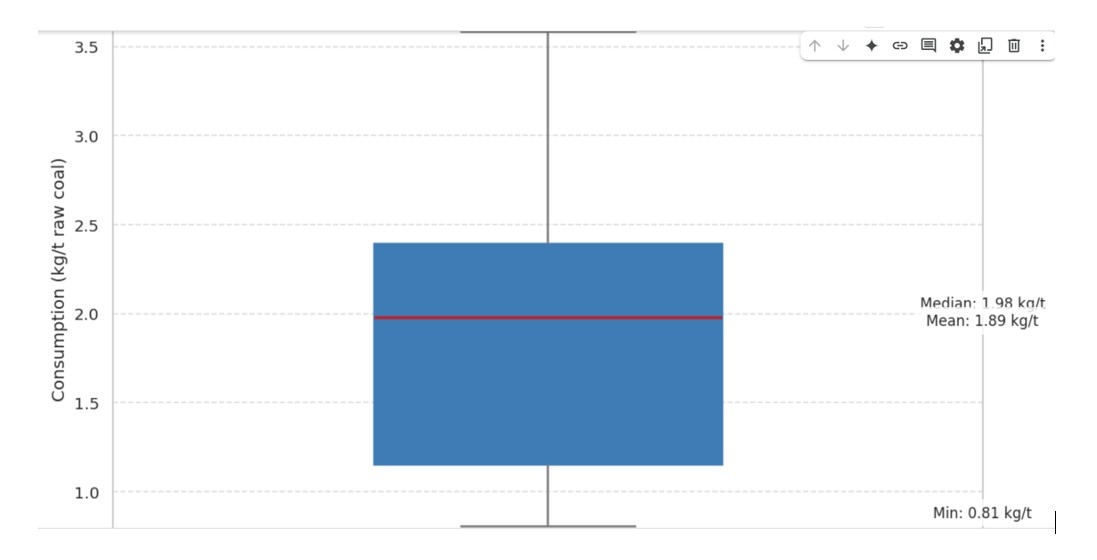

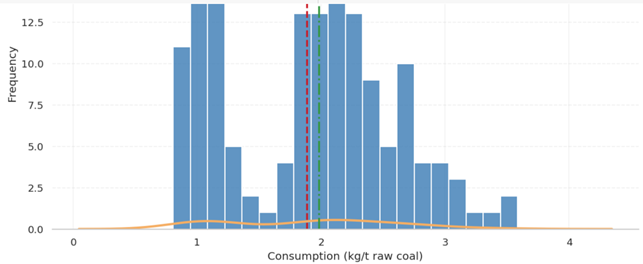

Dense medium separation is the mainstream coal preparation process in China, and the level of medium consumption (referred to as "medium loss" or "magnetite loss") directly affects the economic and environmental performance of coal preparation plants. Medium consumption is typically measured as kilograms of magnetite powder consumed per ton of raw coal (kg/t). Based on industry data analysis, medium consumption in Chinese coal preparation plants shows significant distribution differences and structural characteristics:

Data Distribution of Dense Medium Consumption in Chinese Coal Preparation Plants

Overall Medium Consumption Levels: The average medium consumption in Chinese coal preparation plants ranges between 0.5 to 3.0 kg/t raw coal. Industry-leading plants can control this within 0.8-1.2 kg/t, whereas plants with less stringent management see consumption as high as 2.5-3.0 kg/t or more. This large variation reflects significant disparities in technical equipment and management levels among different enterprises.

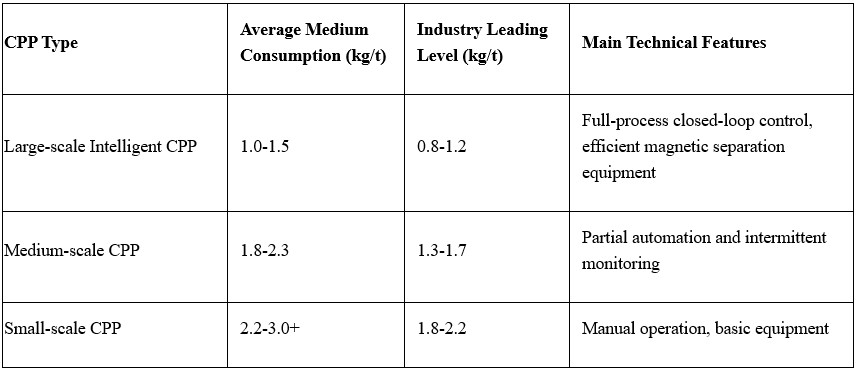

Scale Differences: Large, modern coal preparation plants (annual processing capacity >4 million tons) benefit from advanced equipment and automation systems, achieving an average medium consumption of about 1.0-1.5 kg/t. Small to medium plants (annual capacity <4 million tons), constrained by outdated equipment and insufficient capital investment, have average medium consumption between 1.8-2.5 kg/t. For example, Wuju Coal Company, after intelligent upgrading, reduced medium consumption to industry-leading levels, demonstrating the importance of scale effects and technological upgrades.

Regional Distribution Characteristics: Coal preparation plants in core coal production regions (Shanxi, Inner Mongolia, Shaanxi) have relatively low average medium consumption (1.2-1.8 kg/t) due to scale effects and technological accumulation. Plants in regions like Southwest China and Northeast China tend to have higher medium consumption (2.0-2.8 kg/t) due to older equipment and complex coal quality. Xinjiang plants have medium consumption around 1.5-2.2 kg/t; although higher than core areas, the gap is narrowing with the implementation of the "Xinjiang Coal Export" strategy and introduction of advanced technologies.

Dense Medium Consumption in Different Levels of Coal Preparation Plants in China

Comparison of Dense Medium Consumption in Different Scale of Coal Washing Plants in China

Impact of Coal Quality: Coal types with high gangue content or prone to slimes increase the difficulty of separation and the amount of medium carried with the product, causing medium consumption to rise by 15%-30%. For instance, before optimization, the Zhao Lou coal preparation plant had medium consumption as high as 1.8 kg/t, which was reduced to below 1.3 kg/t after process optimization, significantly improving technical and economic indicators.

Process Route Differences: Plants using a two-stage dense medium cyclone separation process generally have 0.3-0.5 kg/t higher medium consumption than those using a single separation process due to increased system complexity. However, optimizing the medium recovery system (e.g., adding magnetic separation stages) can significantly reduce this gap.

Relationship between Process Route Differences and Dense Medium Consumption

It is worth noting that in 2025, the coal industry faces supply-demand looseness and downward price pressure (the Qinhuangdao port Q5500 thermal coal price fell to 658 RMB/ton, down 173 RMB/ton year-over-year), driving coal washing plants to focus more on cost control. Medium costs account for 25%-35% of dense medium separation costs, second only to electricity consumption. For a plant processing 4 million tons annually, reducing medium consumption by 0.1 kg/t can save over 1.2 million RMB per year, delivering significant economic benefits.

Ⅱ Core Factors Affecting Medium Consumption: Technology, Equipment, and Process Optimization

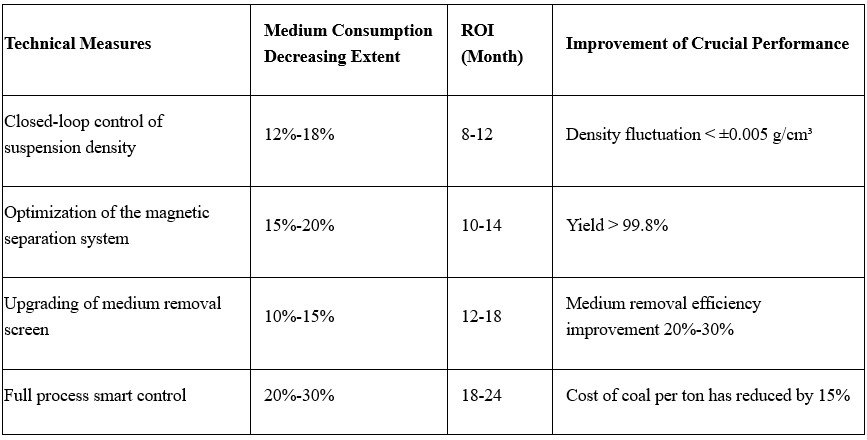

The level of technology, equipment, and process optimization is fundamental and decisive for medium consumption, directly related to medium recovery efficiency and system operational stability. Technical improvements in key production steps can greatly reduce medium loss and achieve scientific control of consumption.

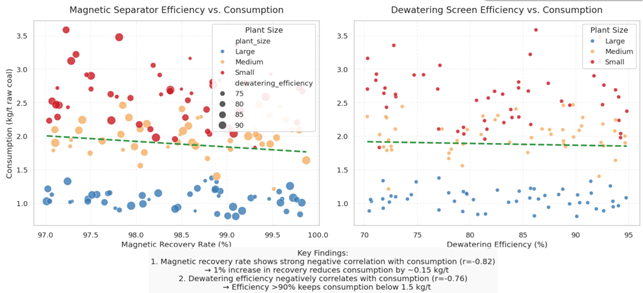

1. Core Role of Magnetic Separator Efficiency

As the last barrier for medium recovery, the performance of magnetic separators directly determines the amount of medium lost to tailings. Selecting and optimizing high-efficiency magnetic separators is the primary technical approach to reduce medium consumption:

Magnetic Field Strength and Recovery Rate: High-quality magnetic separators have magnetic field strengths of 0.15-0.20 Tesla and medium recovery rates exceeding 99.8%, with tailings medium loss controlled below 0.3 kg/t. Ordinary separators only recover 98.5%-99.0%, with tailings losses reaching 1.0-1.5 kg/t, 3-5 times higher. For example, Xiaojihan Coal Mine reduced medium consumption by over 800 tons annually and saved over 2 million RMB after upgrading to a high-gradient magnetic separator.

Equipment Configuration Optimization: Using dual-stage or triple magnetic separator arrangements can significantly improve recovery efficiency. Baodian Coal Mine added a secondary separation system to its single-stage separator, increasing medium recovery by 1.2 percentage points and reducing annual medium consumption by 15%. This configuration is especially suitable for difficult-to-wash coal and high-precision separation requirements.

Feed Concentration Control: The optimal feed concentration for magnetic separators is 20%-25%. Excessively high concentration causes a sharp decline in magnetic separation efficiency. Wangpo Coal Preparation Plant improved magnetic separation efficiency by 8% and saved 300 tons of medium annually by installing automatic concentration monitoring and dilution devices.

Eriez Wet Drum Magnetic Separator

2. Key Impact of Dense Medium Removal Screens

Dense medium removal screens are a core part of the medium recovery system, directly affecting the amount of medium carried away with products and the load on subsequent recovery steps:

Screen Panel Structure and Parameter Optimization:

Using high-efficiency polyurethane screen plates (open area >75%) instead of traditional stainless steel plates (60%-65%) improves medium removal efficiency by 20%-30%. Hecaogou Mine reduced medium carried with product by 0.15 kg/t and saved 450 tons of medium annually by replacing screen panels.

Spray System Upgrades:

Replacing traditional sprays with high-pressure atomized spraying (0.3-0.5 MPa) can increase medium removal efficiency by 15%-25% while reducing water use by 30%. Tunlan Coal Washing Plant optimized spray pressure and angle in its fine coal system, reducing medium consumption by 0.25 kg/t and achieving annual economic benefits of 1.5 million RMB.

Screen Surface Arrangement and Amplitude Adjustment:

Different vibration amplitudes for different particle sizes (4-6 mm for lump coal, 2.5-4.0 mm for fine coal) can significantly improve medium removal. Changping Coal Preparation Plant optimized vibration parameters, increasing medium recovery rate by 2.5% and saving 800,000 RMB annually.

3. Closed-Loop Control Technology for Full Dense Medium Separation Process

Intelligent control systems achieve dynamic optimization and precise control of medium consumption through real-time monitoring and automatic adjustment, representing the development direction of modern coal washing technology:

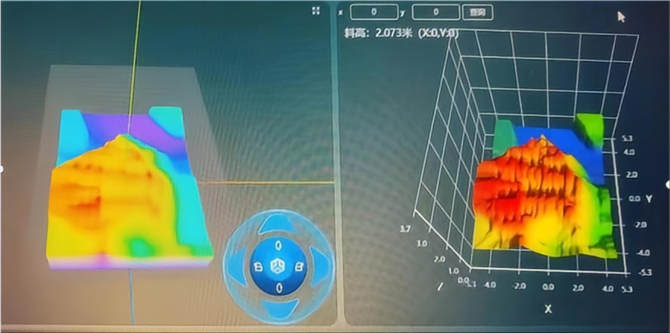

Accurate Control of Suspension Density: Wuju Coal Industry's intelligent washing system uses PID algorithms linked with online density meters to control suspension density fluctuations within ±0.005 g/cm³, improving density stability by 60%, effectively reducing medium waste caused by density fluctuations.

Intelligent Adjustment of Split Flow: Based on real-time monitoring of coal quality and coal slime content in the suspension, the split flow is automatically adjusted to keep magnetic separator feed concentration stable within the optimal range. This reduces medium consumption by 10%-15% and eases the load on magnetic separators.

Stable Control of Cyclone Inlet Pressure: Variable frequency pumps and pressure sensors maintain cyclone inlet pressure fluctuations within ±0.005 MPa to ensure stable separation performance and reduce medium loss caused by insufficient pressure in the underflow.

Influence of Intelligent Upgrading on Dense Medium Consumption

(Due to character limits, please see the remaining content in the next post. Click here)