( Click here to read previous part)

Ⅲ Core Factors Affecting Medium Consumption: Production Management and System Optimization

Apart from technical equipment, scientific production management and system optimization are also key factors in controlling medium consumption. Advanced technical equipment requires refined management to achieve maximum effectiveness. This step is often the main reason for differences in medium consumption between enterprises with similar equipment conditions.

1. Routine Maintenance and Management Measures

The quality of equipment maintenance directly affects system operation stability and medium loss, making it the most basic and critical element in management:

Preventive Maintenance System: Establish regular inspection and condition monitoring systems for key equipment (desliming screens, magnetic separators, centrifuges, etc.) to avoid medium loss caused by sudden failures. According to industry statistics, equipment malfunctions or sudden failures can increase medium consumption per incident by 30%-50%. After implementing an equipment health management system, Wobei Coal Preparation Plant reduced unplanned downtime by 70% and medium loss by 0.15 kg/t coal processed.

Pipeline System Integrity Management: Regularly inspect medium transport pipelines, pump bodies, and storage tanks for wear and leaks, with special attention to elbows, valves, and other vulnerable parts. One coal preparation plant lost more than 20 tons of medium within one month due to undetected pipeline sand holes. After implementing a "daily inspection + intelligent leak monitoring" system, such problems were basically eliminated.

Medium Quality Control: Strictly control the magnetic content (≥95%), particle size distribution (-325 mesh ≥85%), and moisture content (≤8%) of magnetite powder to ensure medium performance meets requirements. Poor quality medium not only increases consumption but also reduces separation efficiency. After establishing medium quality inspection at Tunlan Coal Preparation Plant, medium consumption per ton of coal decreased by 0.1 kg/t.

2. Qualified Suspension Recovery and Medium Retention Technology

Refined operation of the medium recovery process is a direct way to reduce consumption, following three key principles: maximizing recovery of qualified suspension, maximizing medium retention, and maximizing medium recovery:

Control of Qualified Medium Tank Liquid Level and Stability: Maintain liquid level in the qualified medium tank between 60%-70% to avoid pump cavitation from too low liquid or overflow loss from too high liquid. Wangpo Coal Preparation Plant reduced annual medium loss by more than 50 tons through optimized level control.

Optimization of Sieve Bend Operation: Ensure uniform feed distribution on sieve bends, regularly adjust screen decks angles (recommended 45°-55°), and timely replace worn screen plates. Hecaogou Mine’s coal preparation workshop improved medium retention rate by 15% and reduced product medium content by 0.2 kg/t through optimized curved screen management.

Improvement of Centrifugal Liquid Treatment System: Add high-frequency screens or magnetic separators after centrifuges to recover medium from centrifugal liquid. Zhaolou Coal Mine recovered more than 300 tons of medium annually and realized direct economic benefits of 750,000 RMB after adding magnetic separation in the centrifugal liquid circuit.

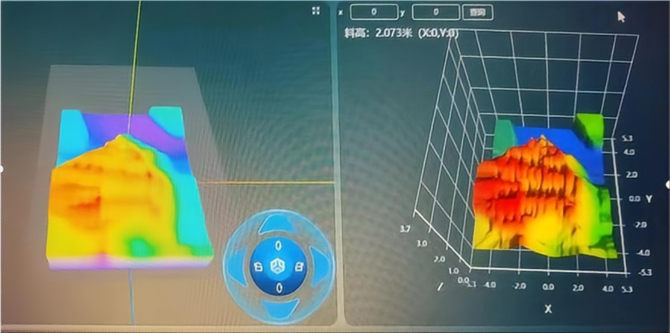

3D Radar of Dense Medium Stockpile

Intelligent Dense Medium Dosing System Built by HOT Industries

3. Intelligent Transformation and System Integration

Intelligent systems achieve fine management and full-process control of medium consumption through data integration and process optimization, representing the highest level of consumption reduction management in coal preparation plants:

Data-Driven Medium Consumption Monitoring: The Wuju Coal Industry intelligent control platform integrates DCS and PLC systems to monitor key indicators such as medium consumption per ton, magnetic separator efficiency, and product medium content in real time, automatically generating consumption curves and warning reports. After implementation, medium consumption per ton dropped 15%-20%, saving 125,000 RMB monthly in electricity, medium, and reagent costs.

Equipment Lifecycle Management: Establish electronic archives for key equipment to track operation parameters, maintenance history, and performance degradation trends, enabling predictive maintenance scheduling. This measure reduced equipment failure rates by 40% and cut unplanned downtime from 55 minutes/day to less than 10 minutes/day, greatly reducing medium loss due to failures.

Digital Twin and Process Optimization: The digital twin system developed by Tup software uses 3D modeling and real-time data mapping to visualize medium flow monitoring. The system can simulate medium consumption under different operating conditions to identify optimal operating parameters. After application in a coal preparation plant, the accuracy of suspension density control improved by 30%, saving 8% of annual medium costs.

Intelligent Dense Medium Dosing System Built by HOT

Ⅳ Typical Cases and Practical Results

1. Wuju Coal Company Intelligent Preparation and Control Platform

The intelligent transformation of Wuju Coal Industry represents the current highest standard in medium consumption control, providing important reference for the industry:

Innovative System Architecture: The platform adopts a "four-layer architecture" (data access layer, infrastructure layer, comprehensive control layer, decision application layer), achieving full closed-loop control of dense medium separation processes. The system covers data collection, process control, equipment management, and energy optimization, solving the traditional problem of information silos in coal preparation plants.

Medium Consumption Control Results: By precisely controlling suspension density (fluctuation < ±0.005 g/cm³) and optimizing medium recovery processes, medium consumption per ton decreased by 15%-20%, and the ash fluctuation range of clean coal was controlled within ±0.5%. Just from medium savings, the platform saved more than 80,000 RMB monthly.

Overall Efficiency Improvement: The plant implemented a "no personnel on-site + remote centralized control" mode, reducing the number of workers per shift from 15 to 6, improving efficiency to 139 tons per worker; equipment failure rates dropped significantly, and continuous material feeding time ratio increased from 65% to over 90%.

2. Zhaolou Coal Mine Comprehensive Medium Consumption Reduction Practice

Facing technical challenges caused by high-ash difficult-to-clean coal, Zhaolou Coal Mine implemented a series of technical and management measures with significant effects:

Process Optimization: Reformed medium recovery process by adding magnetic separation in centrifugal liquid circuit, recovering over 300 tons annually; optimized desliming screen spray system by adopting high-pressure atomization spray, improving medium removal efficiency by 20%, and reducing product medium content by 0.15 kg/t.

Equipment Upgrades: Introduced high-efficiency magnetic separators (recovery rate > 99.8%) replacing older equipment (recovery rate 98.5%), reducing tailings medium loss by 60%; updated polyurethane screen plates (78% open area), tripling screen plate life and improving medium removal by 25%.

Refined Management: Established "daily statistics, weekly analysis, monthly summary" medium consumption management system, linking medium consumption to team performance; strengthened medium quality control, increasing magnetic content requirement from 92% to over 95%. These combined measures reduced medium consumption per ton from 1.8 kg/t to below 1.3 kg/t, generating over 4 million RMB annual economic benefit.

3. Wangpo Coal Preparation Plant Coal Blending Optimization and Medium Consumption Control

Wangpo Coal Preparation Plant addressed large coal quality fluctuations through blending optimization and process control to steadily reduce medium consumption:

Homogenization of Feed Coal Quality: Established raw coal buffer bin and automatic blending system, reducing feed coal ash fluctuation from ±5% to ±2%, decreasing frequency of medium system adjustments caused by coal quality variations.

Automatic Magnetic Separator Feed Concentration Control: Installed online concentration meters and automatic water dosing devices to stabilize feed concentration at 22%-25%, increasing magnetic separator efficiency by 8% and saving 200 tons of medium annually.

Dense Medium System Automation Upgrade: Adopted automatic density adjustment system that adjusts split flow and valve openings based on online clean coal ash detection, reducing lag from manual intervention. After deployment, suspension density stability improved by 40%, medium consumption per ton decreased by 0.2 kg/t.

Dense medium consumption reflects equipment, process, and management integration. In China, consumption ranges from 0.5–3.0 kg/t, with large plants at 1.0–1.5 kg/t and small/medium ones at 1.8–2.5 kg/t. Regional differences persist, and with falling coal prices (e.g., 658 RMB/t), reducing usage is key to cost control.

Technical upgrades like high-efficiency magnetic separators (>99.8%), optimized desliming screens, and closed-loop density control help reduce consumption by 20–30%. Advanced plants achieve suspension fluctuation within ±0.005 g/cm³.

Smart management—routine maintenance, suspension recovery, and intelligent platforms—also contributes. Wuju Coal cut usage by 15–20%, saving 125,000 RMB/month.

Recommendations: upgrade equipment, refine management, promote industry sharing, and seek policy support. With dual drivers of tech and management, medium control will improve by 2030, supporting clean coal and energy transition.